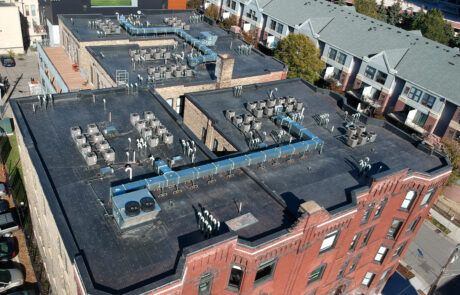

LOW SLOPE ROOFING

Superior Quality, Proven Value

Northway installs & maintains durable EPDM, TPO, BUR roof systems. The diversity of projects we work on covers multi-family, commercial, industrial, & residential properties all over the state of Minnesota.

Northway is partnered with Carlisle & Versico roofing systems. We provide manufacturer low-slope roof warranties for up to 30-years.

We serve the entire state of Minnesota, including Minneapolis, Saint Paul, & the surrounding metro.

What is EPDM membrane?

EPDM single-ply rubber roofing membrane has been an appealing choice of the low-slope commercial roofing industry for over 40-years.

EPDM is an extremely durable synthetic rubber roofing membrane made from Ethylene Propylene Diene Terpolymer. EPDM is most commonly seen as a black membrane color.

EPDM is sold in a broad variety of widths, ranging from 6 feet to 50 feet wide, and 200 feet long, offering options for small to large roof projects.

EPDM is manufactured in numerous thicknesses, from 45 mils to 80 mils reinforced, and non-reinforced.

EPDM roof systems can be installed either fully adhered, mechanically attached, or rock ballasted, depending on the project specifications and needs.

All the seams of the EPDM roofing system are sealed with liquid adhesives and specially formulated butyl flashing tapes, giving long lasting results. EPDM low-slope roofs are time tested membrane roof systems that provide peace of mind and decades of performance.

What is TPO Membrane?

TPO (thermoplastic polyolefin) single-ply membrane roofing systems are built to last. TPO roof systems are known for their heat reflective properties due to their lighter color in white, tan, & grey. TPO can resist damaging ultraviolet, ozone, chemical exposure, and harsh climates.

All TPO is a fiber reinforced membrane that resists long term shrinking.

TPO membrane is fully heat welded at all seams, & flashing details, meaning TPO doesn’t require liquid adhesives or butyl flashing tapes to stay water tight.

TPO can also be installed with a value enhanced (cost saving) Rhino-Bond mechanical attachment, and has the ability to installed in fully adhered, or rock ballasted, depending on the project needs.

Is EPDM or TPO Better?

In recent years there has been a growing demand in both commercial & residential construction for more energy efficient roofing systems to help reduce heating and cooling costs. In response, TPO roof systems have risen to become a leading choice for energy programs and certifications to due its lighter color and heat reflectivity.

Fully-adhered EPDM membrane has been the standard for decades in government funded projects, schools, and urban high-rise developments that demand time tested products, and extended service life.

TPO has become a strong competitor to EPDM in multi-family re-roofs, & commercial developments of almost all types due to the rhino bond system cost savings and innovation.

Both membranes have proven results in countless applications, and it really boils down to each individual budget, building use, & needs.

If you need help in determining which system is right for your property, we are here to help guide you choose the best fit.

Lets Connect…

Please introduce yourself

(we don’t share this info)